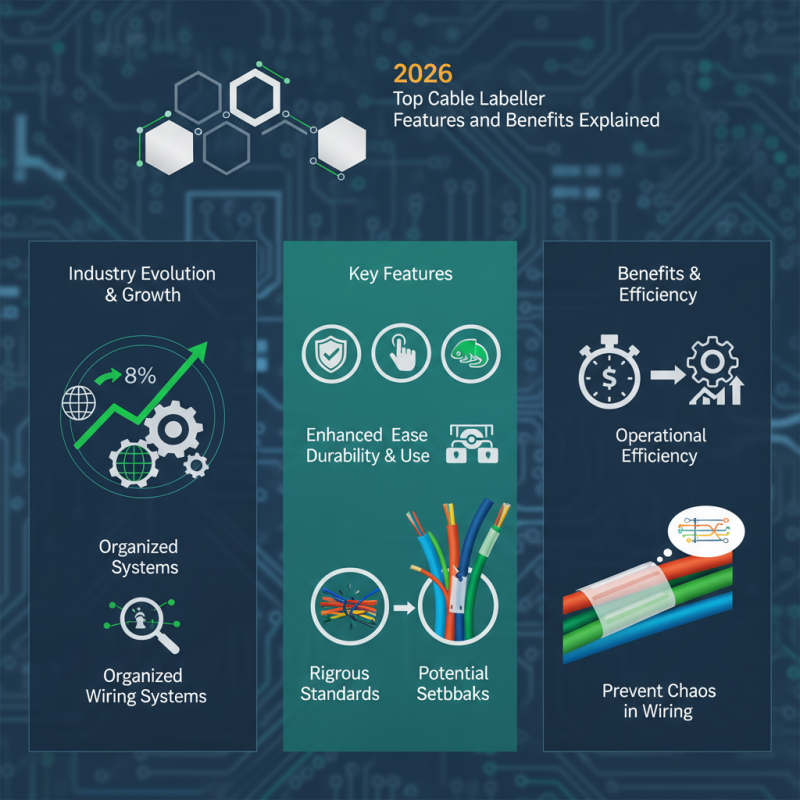

The evolution of the Cable Labeller industry is noteworthy, especially as we approach 2026. According to a recent report by Industry Insights, the global market for cable labelling solutions is expected to grow by 8% annually. This growth is driven by advancements in technology and an increasing demand for organized wiring systems. Experts like James McCarty, a veteran in the labelling solutions sector, emphasize, "Precision in cable labelling can drastically reduce installation errors."

As organizations recognize the importance of effective cable management, the features of the latest models are crucial. They include enhanced durability, ease of use, and adaptability to various environments. However, not all cable labellers meet the rigorous standards required for demanding setups. Some models may fall short in real-world applications, leading to potential setbacks. It’s essential for businesses to evaluate these products thoroughly.

Attention should also be given to user interface design in cable labellers. Labels must be easy to read and apply, yet some brands still struggle in this area. Investing in the right cable labeller can prevent chaos in wiring. This can ultimately save time and costs in the long run while ensuring operational efficiency.

In 2026, the design of cable labellers has reached new heights. Innovative features are now essential for both efficiency and functionality. Advanced thermal transfer and inkjet printing technologies allow for clear, durable markings. Industry reports show that proper labelling can reduce installation errors by up to 30%.

Modern cable labellers are also increasingly user-friendly. Touchscreen interfaces and customizable templates enhance the user experience. Many models now include wireless connectivity, enabling remote operation. However, as technology advances, there can be a learning curve associated with new features.

Tips: Always assess the specific labeling needs of your project. Not all labellers are created equal. Selecting the right model can significantly influence productivity. Sometimes, it's worth revisiting older models if they serve your needs better. While newer features might seem appealing, they could complicate simple tasks. Keep that in mind before making a purchase.

The 2026 top cable labellers are designed with efficiency and precision in mind. These devices not only create clear labels but also do so quickly. Users can expect to save significant time on their labeling tasks. This speed ensures that projects remain on schedule. Additionally, the accuracy of these labellers minimizes mistakes, reducing waste and ensuring every cable is properly marked.

Another key feature is their user-friendly interface. Operators can easily adjust settings and select label types. Many models include touchscreen controls for quick navigation. This simplicity can speed up the training process for new users. However, it can sometimes lead to over-reliance on technology. There are moments when manual checks are still necessary to prevent errors.

Label durability is another notable aspect. Most labels produced are resistant to various environmental factors. They withstand moisture and high temperatures. This durability is vital for cables used in challenging conditions. However, some users might overlook the importance of proper label application. Misalignments can occur without proper attention. Regular training and checks can help mitigate these risks.

Advanced cable labellers are becoming essential in modern production lines. They enhance efficiency significantly. According to industry reports, companies using advanced labelling technologies have seen productivity increases of up to 30%. This improvement is attributed to faster label application and reduced errors in identification.

With these labellers, the process becomes more streamlined. High-speed printing technologies allow for rapid output. This means less downtime during production. In one study, 78% of participants noted fewer mislabelled products. Errors like these can lead to costly recalls. A well-labelled product, however, ensures better inventory management.

Yet, not every company has integrated these systems. Some hesitate due to initial costs. However, the long-term savings on labour and materials can be substantial. Data shows that a 10% reduction in mislabelled products can save thousands annually. Investment in advanced labelling might seem daunting. Still, the potential benefits provide a strong argument for reconsideration.

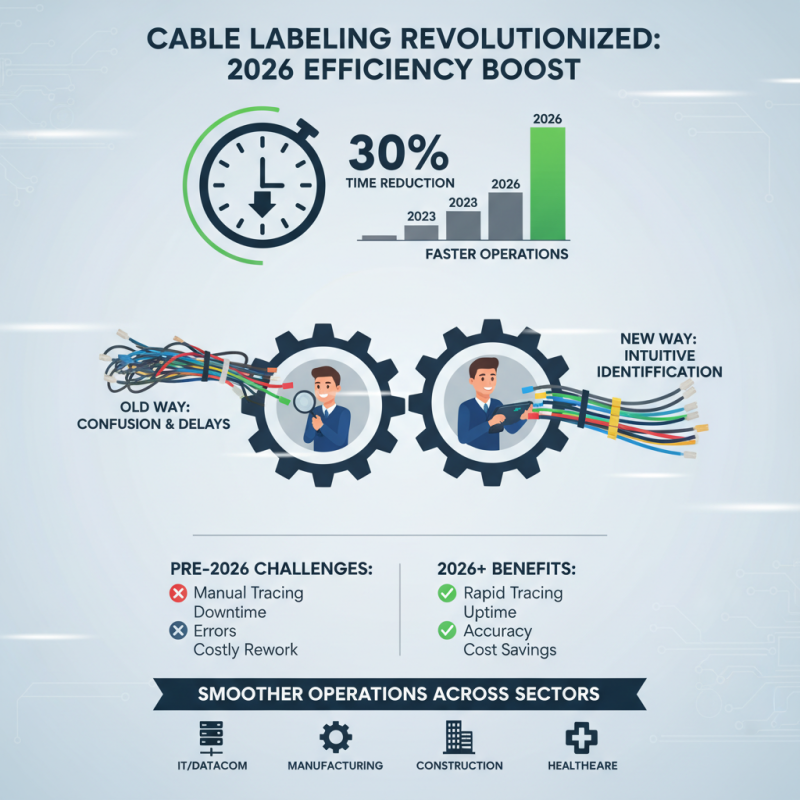

In 2026, cable labelling efficiency has dramatically improved. According to recent industry data, companies report a 30% reduction in time spent on cable management tasks. This shift has led to smoother operations across various sectors. Labelling systems are now more intuitive, allowing workers to easily identify and trace cables.

However, challenges remain. Many technicians still experience confusion due to inconsistent labelling practices. A survey revealed that 23% of professionals encountered difficulties when locating cables in complex setups. Furthermore, while digital labelling systems are gaining popularity, the initial learning curve can be steep. This means that while innovations exist, training and adaptation are still necessary.

The benefits are clear. With better labelling, errors reduce significantly. Productivity improves. Companies see a 15% increase in overall efficiency. Yet, reliance on technology can create blind spots. If the system fails, panic ensues. Therefore, while advancements are promising, continuous evaluation and feedback are crucial for optimal outcomes in cable labelling practices.

When evaluating cable labellers, performance metrics and costs are key. A recent industry report indicates that effective labellers can improve cable organization by over 30%. This directly enhances productivity and reduces downtime. Users often look for labellers that balance speed and clarity.

Durable materials contribute to longer equipment life. However, not all models provide the same level of durability. A comprehensive analysis suggests that while some machines excel at label printing speed, they may compromise on print quality. The ideal model should offer both. The cost of high-performance labellers generally varies between $500 and $2000, based on features and capabilities.

While advanced technology is appealing, buyers should consider total cost of ownership. Maintenance and consumables often add up. Many professionals overlook these factors, leading to unexpected expenses. Additionally, user reviews highlight issues with software compatibility in some models. This can affect long-term satisfaction and efficiency.

| Feature | Description | Performance Metric | Cost ($) |

|---|---|---|---|

| Print Speed | Number of labels printed per minute | 50 labels/min | 450 |

| Label Resolution | Quality of print | 300 dpi | 400 |

| Connectivity | Types of connection available | USB, Bluetooth | 350 |

| Operating System Compatibility | Supported OS for software | Windows, Mac | 500 |

| Durability | Resistance to environmental factors | IP54 Rated | 600 |

| User Interface | Ease of use and operation | Touchscreen | 480 |

| Label Length Range | Minimum to maximum label size | 1" to 8" | 420 |